Press Fit Interference Chart

Press Fit Interference Chart - Using a 25 mm diameter, a h7/p6 fit gives a min interference of 0.001 mm and a max interference of 0.035 mm. The coefficient of expansion of material considered should be checked against the basis temperature of 70 deg f. Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Unlike transition fit and clearance fit, interference fit forms a permanent coupling of two components. Assembly can be performed with cold pressing.

Assembly can be performed with cold pressing. Fit for accurate location, assembly by mallet or press; Heavy press or shrink fit not meant for dissassembly; The coefficient of expansion of material considered should be checked against the basis temperature of 70 deg f. For when mating parts must behave as a single piece

Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron. Shaft p6 with hole h7 gives a true interference fit. Fit for accurate location, assembly by mallet or press; Fit for parts requiring rigidity and alignment with accuracy; Assembly can be performed with cold pressing.

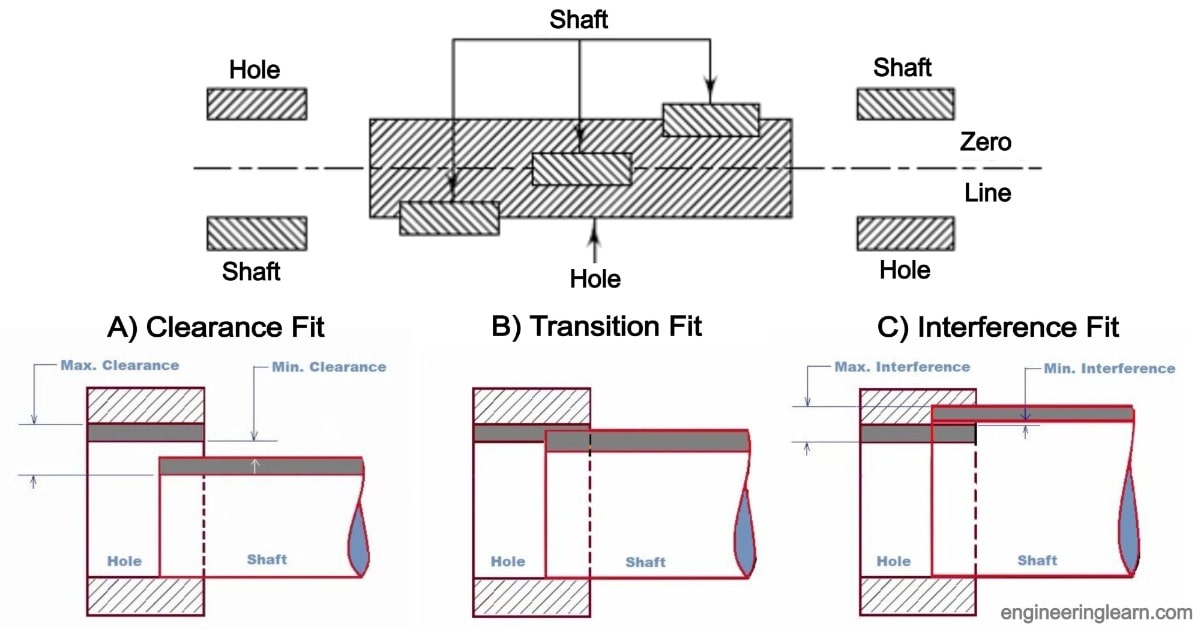

Shaft p6 with hole h7 gives a true interference fit. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Unlike transition fit and clearance fit, interference fit forms a permanent coupling of two components. Press fit (interference) an interference (press) fit is a type in which the shaft is.

Assembly can be performed with cold pressing. For when mating parts must behave as a single piece The amount of interference is too small for satisfactory press fit to be obtained in materials of low modulus of elasticity such as light alloys. Locational interference fit for parts requiring rigidity and alignment with prime accuracy of location but without special bore.

Unlike transition fit and clearance fit, interference fit forms a permanent coupling of two components. It creates a frictional force that holds the parts together without the need for additional fasteners or adhesives. Interference fit calculator to calculate press fit force, shrink fit temperature and von mises stresses occurred on shaft and hub. The amount of interference is too small.

Interference fit calculator to calculate press fit force, shrink fit temperature and von mises stresses occurred on shaft and hub. Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron. It creates a frictional force that holds the parts together without the need for additional fasteners or adhesives. Locational interference.

Press Fit Interference Chart - It is the standard press fit for steel , cast iron, or brass to steel assemblies. Shaft p6 with hole h7 gives a true interference fit. Unlike transition fit and clearance fit, interference fit forms a permanent coupling of two components. Assembly can be performed with cold pressing. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron.

Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Assembly can be performed with cold pressing. Locational interference fit for parts requiring rigidity and alignment with prime accuracy of location but without special bore pressure requirements. The amount of interference is too small for satisfactory press fit to be obtained in materials of low modulus of elasticity such as light alloys. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity.

Interference Fit Calculator To Calculate Press Fit Force, Shrink Fit Temperature And Von Mises Stresses Occurred On Shaft And Hub.

Fit for accurate location, assembly by mallet or press; The amount of interference is too small for satisfactory press fit to be obtained in materials of low modulus of elasticity such as light alloys. It is the standard press fit for steel , cast iron, or brass to steel assemblies. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity.

Medium Drive Fit For Ordinary Steel Parts Or Shrink Fits On Light Sections, The Tightest Fit Usable With Cast Iron.

Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Heavy press or shrink fit not meant for dissassembly; Using a 25 mm diameter, a h7/p6 fit gives a min interference of 0.001 mm and a max interference of 0.035 mm. The coefficient of expansion of material considered should be checked against the basis temperature of 70 deg f.

It Creates A Frictional Force That Holds The Parts Together Without The Need For Additional Fasteners Or Adhesives.

Press fit (interference) an interference (press) fit is a type in which the shaft is larger than the hole (before assembly). Unlike transition fit and clearance fit, interference fit forms a permanent coupling of two components. Assembly can be performed with cold pressing. Locational interference fit for parts requiring rigidity and alignment with prime accuracy of location but without special bore pressure requirements.

For When Mating Parts Must Behave As A Single Piece

Fit for parts requiring rigidity and alignment with accuracy; Shaft p6 with hole h7 gives a true interference fit.